OUR EXPERTISE

Gerling’s core areas of expertise include assembly facilities with customised process integration. These facilities are frequently used to assemble components in the automotive industry:

- Transfer lines

- Robot cells

- Machine linking

- Rotary indexing machines

- Manual work stations

Thanks to our reliable team of employees and their many years of experience, all of our expertise is in-house:

- Systems design using 3D CAD work stations

- Parts production using modern CNC machines

- Electrical planning and software development

- System installation, electrical installation and commissioning

- Customer service and hotline for remote maintenance

Gerling’s core areas of expertise include assembly facilities with customised process integration. These facilities are frequently used to assemble components in the automotive industry:

- Transfer lines

- Robot cells

- Machine linking

- Rotary indexing machines

- Manual work stations

Thanks to our reliable team of employees and their many years of experience, all of our expertise is in-house:

- Systems design using 3D CAD work stations

- Parts production using modern CNC machines

- Electrical planning and software development

- System installation, electrical installation and commissioning

- Customer service and hotline for remote maintenance

Customer advisory service

Analysis of the required production processes, advice that is up-to-date with the latest technology and creation of a customer-specific quote.

Product development

Development and design of an automation solution that is specially customized.

Project implementation

Manufacture and assembly of your system using our expertise and high-quality components.

Commissioning and training

Commissioning of the automation solution at your site as well as training of your employees for operating the system.

After sales service

Support through professional telephone advice, digital remote maintenance and on-site service from our qualified employees. Delivery of spare parts from our well equipped warehouse. Adaptation of your automation systems to changed production conditions.

OUR FIELDS OF EXPERTISE

Parts handling

Using special manipulators such as Pick + Place units and robots, parts are transported and positioned extremely precisely in no time at all.

Palletisation| Magazining | Loading | Unloading

Palletisation | Magazining | Loading | Unloading

Palletisation | Magazining | Loading | Unloading

Feeding technology

Customers’ parts are carefully fed as bulk goods, for instance, by special feeding systems on conveyor belts or linear conveyors so that they arrive in the correct position for the production process.

Sorting | Separation | Dispensing

Sorting | Separation | Dispensing

Sorting | Separation | Dispensing

Joining processes

Components are joined together using a variety of joining techniques.

Screw connection | Adhesive | Hard soldering | Pressing in |

Ultrasonic welding | Resistance welding

Screw connection | Adhesive | Hard soldering | Pressing in |

Ultrasonic welding | Resistance welding

Screw connection | Adhesive

Hard soldering | Pressing in

Ultrasonic welding

Resistance welding

Parts processing

Parts processing is carried out using various methods, for example:

Forming | Bending | Punching | Separating | Drilling | Grinding | Milling

Forming | Bending | Punching | Separating | Drilling | Grinding | Milling

Forming | Bending | Punching

Separating | Drilling | Grinding | Milling

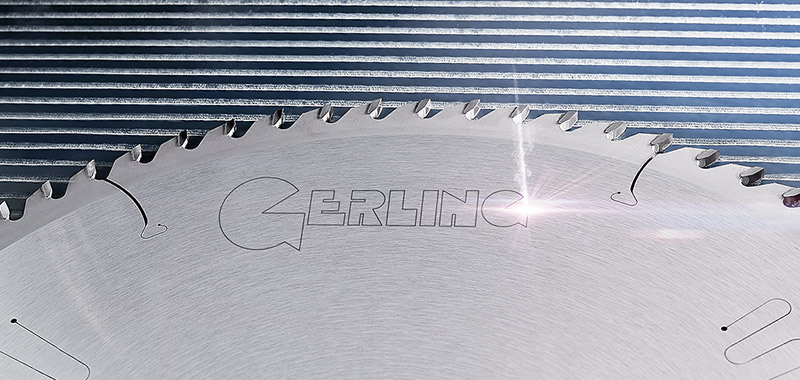

Marking technology

Component identification is carried out using various methods, for example:

Marking

technology

Component identification is carried out using various methods, for example:

Laser marking | Labelling | Stamping | Engraving

Laser marking | Labelling | Stamping | Engraving

Laser marking | Labelling

Stamping | Engraving

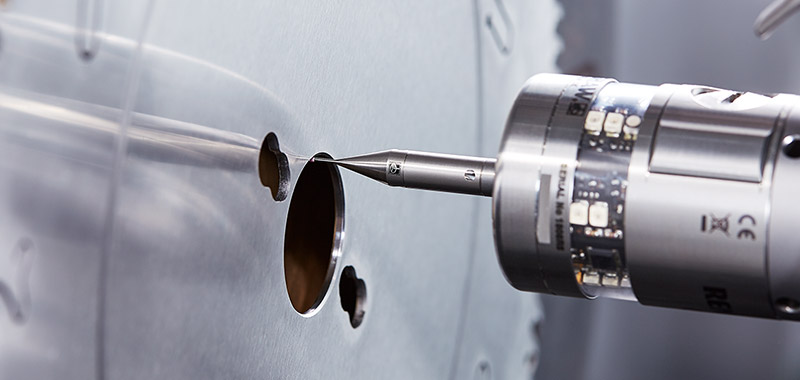

Testing and measuring technology

To guarantee the function and quality of our components, they are subjected to various tests and measurements.

Tactile measurement | Optical measurement | Electrical testing |

Leak testing | Strength testing | Eddy current testing

Tactile measurement | Optical measurement | Electrical testing |

Leak testing | Strength testing | Eddy current testing

Tactile measurement

Optical measurement

Electrical testing

Leak testing

Strength testing

Eddy current testing

LOOKING FOR A UNIQUE OR CUSTOMIZED SOLUTION?

Feel free to contact us.